Sustainable energy and transport, shared autonomy, and saving the world. Here’s how Elon Musk’s vision is becoming reality.

Tesla Master Plan, Part 1

From 0 to Mainstream: Hot off the heels of his PayPal victory and determined to change the status quo, Musk launched Tesla in 2003, at the same time he was building SpaceX. His Master Plan for the nascent company was essentially as follows:

- Build sports car that runs on zero-emission electric power generation

- Use the revenue to build an affordable electric car

- Use that revenue to build an even more affordable electric car

“The strategy of Tesla is to enter at the high end of the market, where customers are prepared to pay a premium, and then drive down market as fast as possible to higher unit volume and lower prices with each successive model,” he writes on Tesla’s blog.

1. Create a low volume car, which would necessarily be expensive

Source: Tesla.com

Source: Tesla.com

The Roadster, Redefining The Electric Car: Tesla debuted the Roadster, a luxury electric sports car, in 2008. The vehicle was the first mass-produced electric car to use lithium-ion batteries, and the first to travel more than 200 miles on a single charge.

Just as he envisioned, the Roadster immediately broke preconceptions about what an electric car could be. The vehicle set the world distance record of 501 km for a production electric car on a single charge in October 2009; It could accelerate from 0 to 60 mph in less than four seconds.

Tesla sold 2,450 of these high-end sports cars at a base price point of $109,000, and funneled the revenue into development of the Model S.The company stopped producing the Roadster in 2012, and plans to replace it with a second-generation version in 2019. Even so, the original Roadster served its purpose by raising eyebrows, funding the Model S, and setting Tesla’s Master Plan into motion.

Musk put as much of the profits from the Roadster as possible back into research and development, with the aim of creating a slightly more affordable but still luxurious family-oriented car.

2. Use that money to develop a medium volume car at a lower price

Source: Tesla.com

Source: Tesla.com

Model S, Setting the Standard for Luxury Cars: Telsa released the Model S, a second-generation luxury vehicle at a lower price point, in 2012. The new model became one of the top-selling all-electric vehicles in the world and won numerous awards, including Time Magazine’s Best 25 Inventions of the Year Award in 2012 and Motor Trend Car of the Year in 2013.

Model X, Addressing the Other Half of the Car Market: Tesla rolled out the Model X, a luxury SUV sporting falcon-wing doors, in September 2012. While the model was absent from the company’s original master plan, Musk couldn’t ignore the fact that SUVs comprised 50% of the vehicle market.

The car was difficult to manufacture, and the pace of deliveries suffered. Soon after its release, a litany of glitches appeared. While many were related to the falcon-wing doors (such as the possibility of injury while closing), customers also reported issues with stubborn front doors, frozen touch-screens, and underperforming heaters. Elon now refers to the Model X as “step 2.5” of his Master Plan, and claims that Tesla’s “hubris” in adding so many new features was the source of its flaws.

3. Use that money to create an affordable, high volume car

Source: Tesla.com

Source: Tesla.com

Model 3, Mass-Market Adoption: With the Model S and Roadster under its belt and the Model X behind it, Tesla is now working on the key piece of its strategy—a high-volume car with a low price point. Meant for the masses, the Model 3 will start at a mere $35,000 before government incentives.

More than 100,000 pre-orders for the Model 3 flooded in sight-unseen in the 24 hours before Musk even displayed the prototype in March 2016. There were roughly 400,000 total pre-orders as of May 2017.

Production of the Model 3 is slated to begin in mid-2017 and ramp up to 500,000 cars per year in 2018. The first deliveries are scheduled for late 2017.

4. Provide solar power

Solar roof tiles. Source: Tesla.com

Tesla Acquires SolarCity for a “Whole-Home” Energy Solution: While the Powerwall can work in concert with solar panels and Tesla car chargers, truly seamless integration would require a merge between SolarCity and Tesla, Musk decided. Tesla bought SolarCity in 2016, moving Musk one step closer to his vision of a comprehensive energy solution for consumers, complete with rooftop solar generation, battery storage, and electric vehicle charging. SolarCity is slated to begin producing solar panels at its own gigafactory in Buffalo, New York in the summer of 2017.

Re-Inventing Solar for the Mass Market: With the other pieces of the renewable energy puzzle in place, Musk felt it was it was time to take rooftop solar to the next level. That meant a differentiated solar product with curb appeal for the masses—the solar roof.

Tesla rolled out roof tiles with invisible solar cells to widespread acclaim in October 2016. The tiles provide greater coverage with a seamless, integrated aesthetic. Homeowners can choose from four different styles that mimic traditional shingles. Made of tempered glass, they’re also quite tough; the tiles are designed to withstand hail impacts of up to 200 mph. Tesla’s solar roof lasts longer than a traditional roof, and at a lower cost when factoring in the electricity it generates.

The solar roof product was approved for permitting and installations by from Underwriters Laboratories (UL) in May 2017, and installations will begin in California in June 2017. Inventory has already sold out well into 2018.

Tesla Master Plan, Part 2

With the company’s initial goals well on their way to fruition, Musk publicly expanded his Master Plan in a 2016 blog post. He mapped out Tesla’s future endeavors as follows:

- Integrate energy generation and storage

- Expand to cover the major forms of terrestrial transport

- Implement self-driving technology

- Enable car sharing

1. Integrate Energy Generation and Storage

Source: Tesla.com

Home storage: Storage has long been considered the “holy grail” for solar. When paired with storage, intermittent renewables like solar and wind can be just as reliable as energy based on fossil fuels. Storage can also sync solar production (which peaks at midday) with demands on the grid (which spike in the morning and evening).

While there are various ways to store energy, batteries are the only practical option for homes. Still, household-sized batteries remained expensive and difficult to maintain. Musk knew that solving storage would change the game for solar.

He achieved this goal in 2015 when Tesla released the Powerwall, a rechargeable lithium-ion battery for residential storage, and the Powerpack, a larger version for commercial and utility-scale projects.

The attractive, sculpture-like Powerwall simply mounts to an external or internal wall, and requires little maintenance. It debuted at an astonishing $3,000, and sold out through the following year almost immediately.

Scaled Battery Production: Musk knew that making batteries attractive and affordable wasn’t enough—rooftop solar with storage had to meet or beat the utilities on cost per watt. That meant large-scale production.

In 2013, Tesla announced plans to build a massive “gigafactory” near Reno, Nevada. While the facility is still under construction, it began producing battery cells for Powerwalls and Powerpacks in January 2017. The factory is about 30% complete, with roughly 4.9 million square feet of operational space planned. That figure may eventually double. Even at its originally planned footprint, the facility is the world’s largest building by square footage. Boeing’s plant in Everest, Washington comes in second at 4.3 million square feet.

Source: Tesla.com

The massive facility will manufacture 35GWh of battery cells and 50GWh of packs per year by 2020, all with renewable energy. Production at the gigafactory will likely slash the cost of batteries by more than 30%. A total of just 100 such facilities could provide the storage needed to transition the entire world to sustainable energy.

While Tesla can’t build all 100 of them, Gigafactory 1 is just the beginning. The company will also release plans for 2-4 new gigafactories later this year. Musk is hoping that other companies follow his lead and build their own gigafactories to address the world’s energy needs.

2. Expand Into All Forms of Ground-Based Transportation

With the SolarCity deal locked in and construction on Gigafactory 1 underway, Tesla could focus on the next phase of its Master Plan—expanding its line of vehicles. A full transition from fossil fuels to clean energy would require heavy-duty electric trucks and vehicles for shipping goods, in addition to passenger sedans and SUVs.

Tesla Semi. In December of 2017, Musk unveiled the Tesla Semi. Musk projects the new vehicle will beat diesel trucks on cost per mile, and has an estimated range of up to 500 miles. Tesla plans to begin production of the vehicle in 2019.

Next-Gen Tesla Roadster. At the Tesla Sami unveil event, Elon Musk surprised the audience by revealing a refresh of the car that originally launched Tesla, the Roadster. Boasting a record-braking 0-60 mph acceleration of 1.9 seconds and 620 miles of range, the the new Roadster aimed to provide “the hardcore smackdown” to internal combustion engine vehicles.

Cybertruck. On November 21, 2019 Tesla launched its entry into the lucrative pickup market with the unveil of Cybertruck. “It doesn’t look like anything else,” proclaimed Elon once the truck came onstage. As the demonstration continued, it became clear that the Cybertruck did not have the specs and performance of anything else, either. Drawing from innovations at SpaceX, the Cybertruck abandoned the traditional body on frame design of all other cars in favor of cold-Rolled stainless-steel exoskeleton.

During a demonstration gone awry, Franz von Hozhausen threw a steel ball that shattered two of the trucks windows. Between the botched demonstration and the futuristic cyberpunk appearance of the truck, the unveil made waves across the media, internet, and cultural zeitgeist.

3. Vehicle Autonomy

Musk plans to roll out autonomous capability as soon as possible, and not just for the coolness factor—he’s primarily concerned with safety. Tesla will integrate self-driving components such as cameras, radar, and sonar with all of its vehicles as the technology evolves, he reports. Autonomous systems will be fail-operational, meaning that a vehicle will still drive itself safely if a component system breaks. While it will be some time before self-driving vehicles become street-legal, Tesla cars will be ready.

“I should add a note here to explain why Tesla is deploying partial autonomy now, rather than waiting until some point in the future,” Musk writes on Tesla’s blog. “The most important reason is that, when used correctly, it is already significantly safer than a person driving by themselves and it would therefore be morally reprehensible to delay release simply for fear of bad press or some mercantile calculation of legal liability.”

4. Sharing

Once your car is self-driving, you can put it to work for you when you’re not using it, Musk says. It will essentially be an “Uber driver,” but in Tesla’s shared fleet. Your Tesla may eventually end up paying for itself, meaning that anyone could afford to buy one.

It’s a win-win for both Tesla and the consumer, and the final phase of Tesla’s Master Plan—as far as we know. Judging from the company’s history, it could be the path to funding “Master Plan: Phase 3.” Musk may just be getting started.

Tesla Master Plan, Part 3

The focus of Tesla’s previous “master plan” unveilings largely centered around a new product line that the company would be adding to its suite of offerings. The roll out of Master Plan 3 at Tesla’s Investor Day on March 1, 2023 had a bit of that, but this event was notably different as Musk went “big picture” to outline the company’s next area of focus – completely ending fossil fuels.

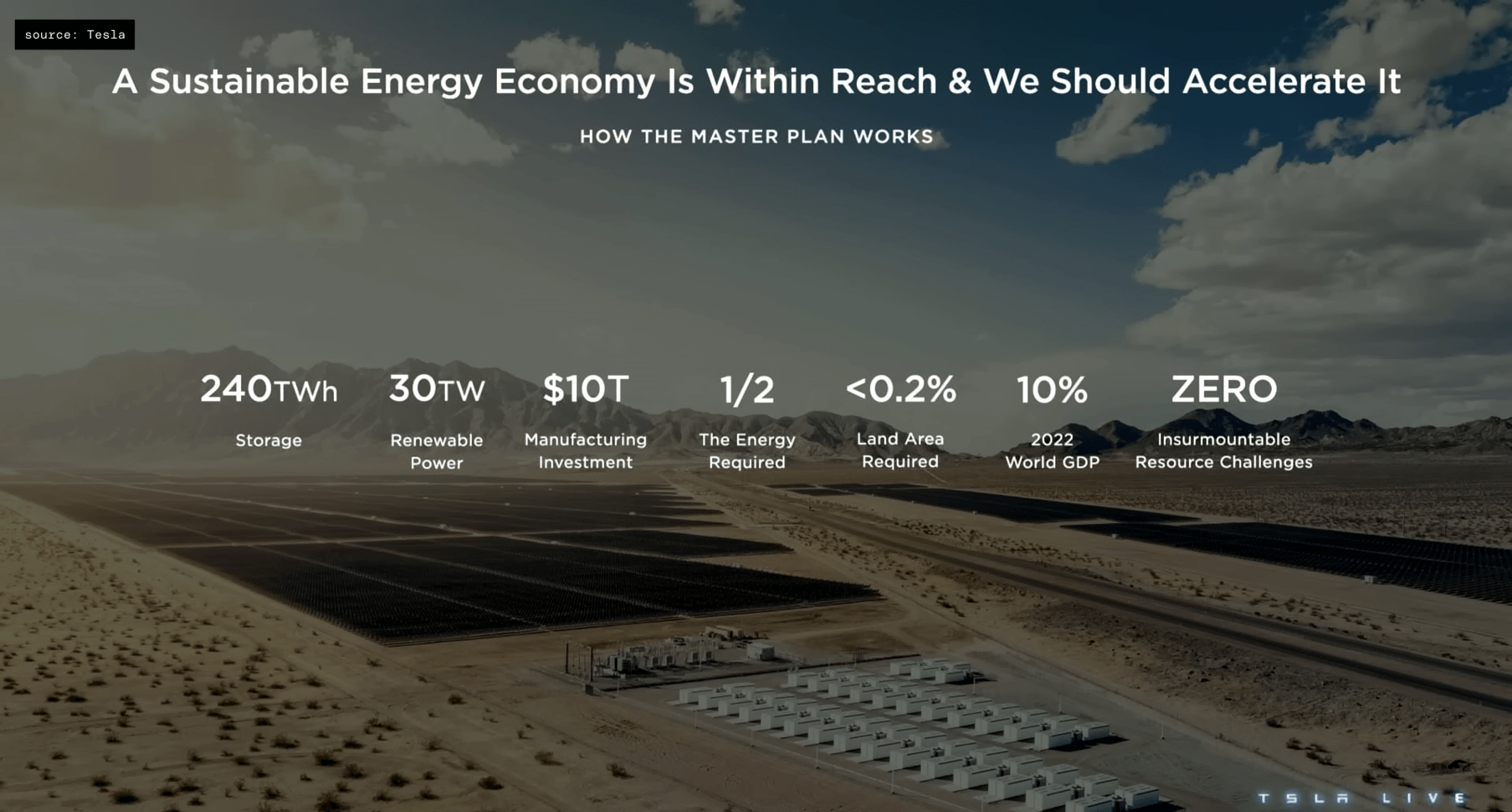

To accomplish this ambitious goal, Musk outlined the need to invest $10 Trillion in new manufacturing operations focused on rapidly increasing the clean energy transition.

The Numbers

The plan calls for a massive increase in battery storage in the form of both stationary storage and electric vehicles. Tesla estimates that 240 TWh of storage will need to be in place with about 30 TW of renewable energy to support a truly sustainable existence on Earth. Musk pointed out that even in this scenario, wind and solar resources would occupy less than 0.2% of land on Earth, and contrary to popular belief, the availability of natural resources and minerals needed to accomodate this transition would be sufficient to meet demand.

The Plan

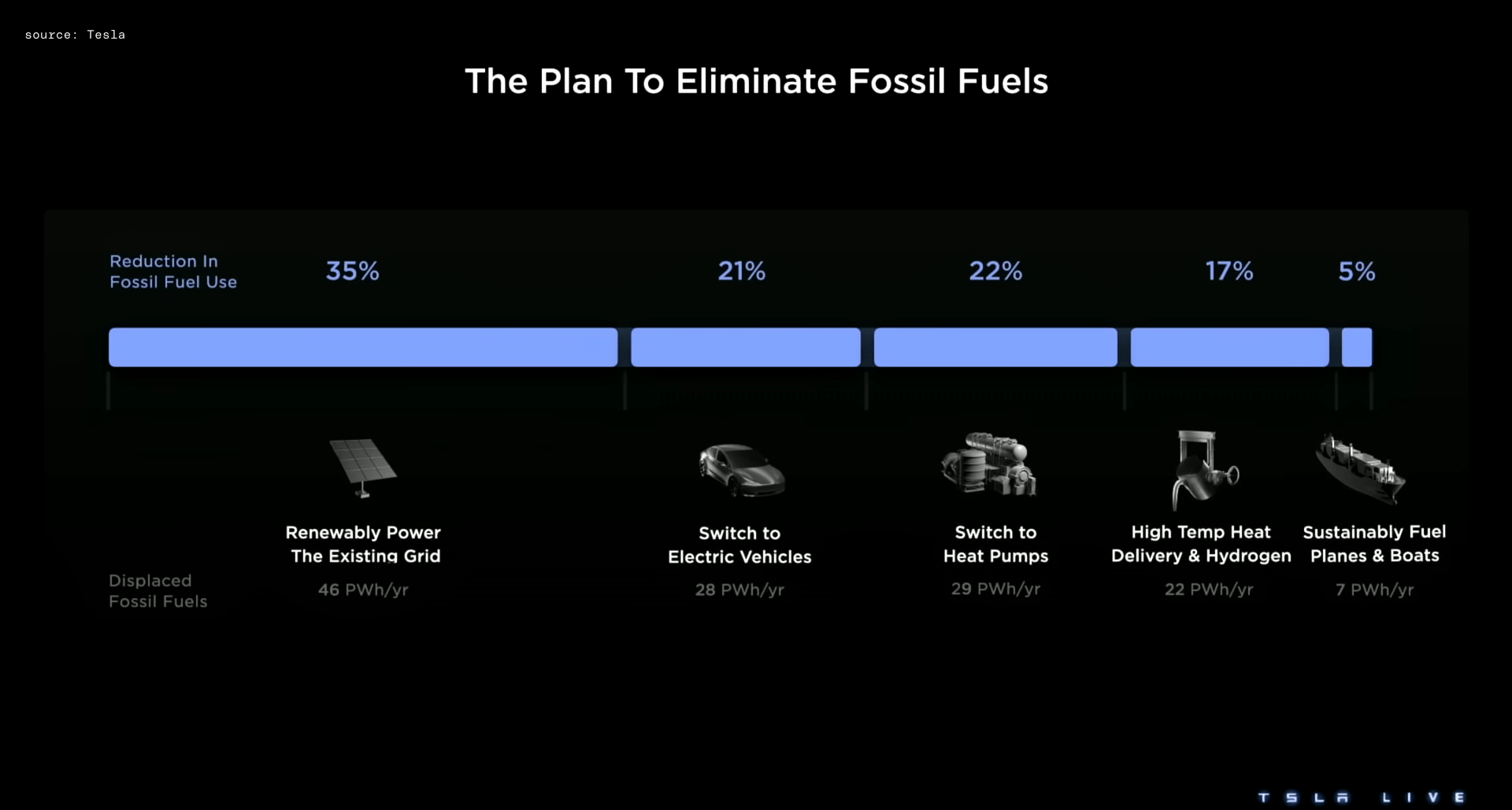

Musk outlined the need to dedicate the $10 Trillion investment across a range of products and industries:

- Adding renewable power to existing grid infrastructure

- Bringing more electric vehicles to market

- Installing heat pumps in residential and commercial buildings

- Using high-temperature heat delivery and hydrogen for industrial applications

- Bringing sustainably fueled planes and boats to market

Mystery Vehicle Key to Production Ramp

At the Investor Day event , Musk and other Tesla executives took the opportunity to reiterate the company’s goal to produce 20 million electric vehicles annually by the year 2030. Tesla claimed 1.3M deliveries in 2022, making it clear that the company will have to overhaul its production processes and capabilities in order to meet their lofty goals.

Musk confirmed that Tesla’s sixth gigafactory would be built south of the border in Monterrey, Mexico. At a price tag of over $5 Billion, the mammoth facility will be almost double the size of the Austin, TX gigafactory, making it the largest electric vehicle production facility in the world. The mission of this gigafactory will be a pivotal one as it will be where Tesla’s mysterious next-gen class of vehicles will be built. Musk was predictably tight-lipped on details of the line of vehicles, but it was clear that slashing prices for the consumer by improving manufacturing efficiencies is the focal point.

Tesla Turns Focus to Affordability

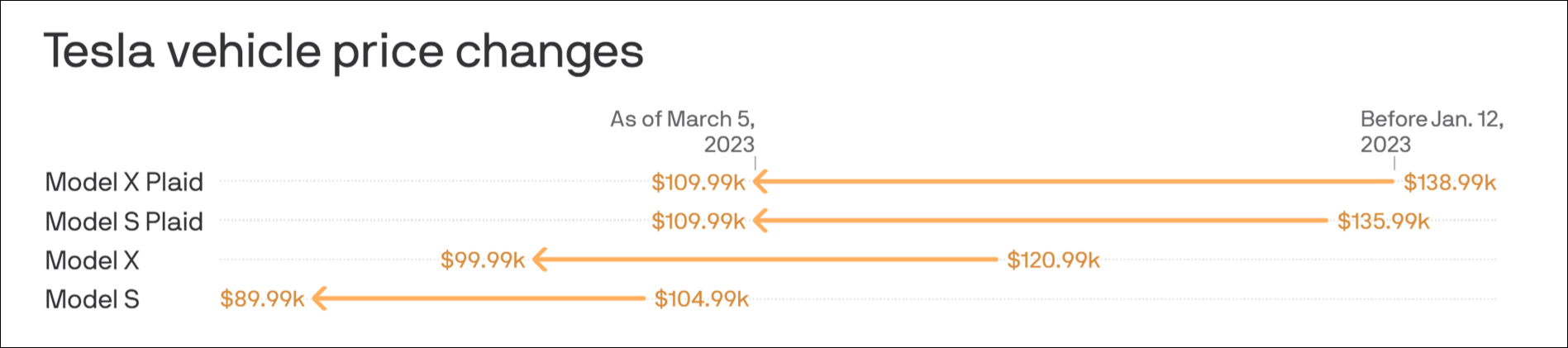

Earlier this year, Tesla slashed prices on their Model S and Model X vehicles in an effort to draw even more interest from consumers.

At Investor Day, Musk reported that this move yielded successful results, and it is clearly just the beginning of Tesla’s efforts to make affordability a central tenet of its next-gen vehicles. “We found that even small changes in the price have a big effect on demand…very big,” as Musk put it at Investor Day.

The Tesla team said that the next-gen vehicles will have a 40 percent smaller manufacturing footprint and would cut production costs by 50 percent. Tesla executive Tom Zhu, who leads global production and is the highest profile exec after Musk, pointed out the company’s increasingly efficient production capabilities that will be a critical trend moving forward as Tesla seeks to significantly ramp production. As Zhu said, “It took us 12 years to build the first million [cars], and about 18 months to the second million. The third million, 11 months. Then less than seven months to build the 4 millionth.”

The big picture goals set forth by Musk via his latest Master Plan chapter are exciting and underscore how Musk sees Tesla’s tentacles interacting with nearly every facet of the renewable energy transition. The more exciting news for consumers is the next-generation of vehicles that Tesla has up their sleeves and the company’s renewed commitment to making their vehicles more affordable.

Tesla’s full Master Plan 3 unveiling at its March 1, 2023 Investor Day can be viewed at the below link