Despite many people assuming that the bulk of upfront solar power costs come from the manufacture of solar PV panels, soft costs– such as planning and installation labor– actually account for well over half of the average solar system.

Minimizing these soft costs presents great opportunity to increase the access to residential solar and hasten payback periods for homeowners, breaking down a significant barrier for families to take advantage of solar and for installers to gain customers.

Given that solar PV systems can cost customers tens of thousands of dollars, any improvement to the affordability of solar can provide great impact to installers and the industry as a whole. Despite the focus on improving solar technologies, both in efficiency and cost, many strategies exist to minimize these initial and one-time soft costs that can be just as impactful to the propagation of clean and renewable solar power to homes and businesses across the world. The Solar Energy Industries Association agrees, noting that “the biggest cost-decline opportunity in residential and small commercial solar exists in soft costs.”

What Are Soft Costs?

Specific cost breakdowns of solar panel systems for homes vary according to numerous factors, including 1) size of the installation, 2) region in which the installation takes place, 3) government incentives available, 4) manufacturer and installer chosen, 5) periphery technology like tracking the sun, 6) the permitting process in a particular community, and much more. Regardless, though, soft costs actually make up a majority of the final investment for homes installing solar panels.

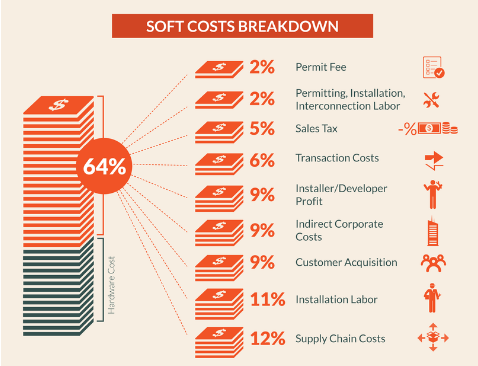

Soft costs are any costs that do not pay for direct hardware of the solar panels or the inverter themselves. Those hard costs, according to the U.S. Department of Energy, only make up about 36% of a customer’s initial investment and the remaining 64% goes to the variety of soft costs. Assuming an average 5.7 kilowatt residential solar rooftop system (a size used as a benchmark by the National Renewable Energy Laboratory) that would cost $15,960, the breakdown of costs might look something like the following:

Hard Costs:

- Solar Panel Costs: $3,990.00

- Inverter Costs: $1,436.40

Soft Costs:

- Permit Fee: $319.20

- Permitting, Installation, Interconnection Labor: $319.20

- Sales Tax: $798.00

- Transaction Costs: $957.60

- Installer/Developer Profit: $1,436.40

- Indirect Corporate Costs: $1436.40

- Customer Acquisition: $1436.40

- Installation Labor: $1,755.60

- Supply Chain Costs: $1915.20

While solar hardware costs have dropped dramatically in recent years, the low-hanging fruit of soft costs have not been addressed as widely. That said, soft costs are universally burdensome and any efforts to bring them down will be of wide benefit to the solar community. Obviously not all of those soft costs mentioned above can be targeted by everyone in the process (e.g., a customer can’t do anything about the indirect corporate costs), but some effective strategies to minimize the soft costs follow.

Photo Source: SEIA

Targeting Time Required for Installations

The first place to start when it comes to minimizing soft costs to solar systems is to address any inefficiencies during the installation process, both cost efficiencies and time efficiencies. The strategies for making installations quicker and easier expand across technology and process. According to a study from the Rocky Mountain Institute, the greatest opportunities in this regard include:

- Enhancing technologies and processes to the point that installations can be completed in a single day;

- Integrating strategies to improve the racking base installation process; and

- Using standardized solar systems, where possible, to eliminate the need for excessive design work for each individual project.

Each of these methods will have significant results in bringing down the length of time workers need to labor in order to get solar systems up and running. To complete installations in a single day, careful planning of the install strategy can ensure the right workers are there to maximize efficiency and reduce the iterative costs of various fixed costs associated with each individual visit. This goal can be achieved through task specialization, designing systems consistently so workers know exactly how to implement them upon arrival on site, or even with the aid of satellite/aerial imaging of the install site to get ahead of any potential challenges.

Improving the rack base installation process could require periodic evaluations of the racking base systems used by installers to determine if new products come available to the market that can cut install times and costs. Esdec, for example, recently came to the U.S. market offering its innovative twist on solar rooftop mounting that utilizes self-levelizing baseplates that are designed to reduce installation times (read more about Esdec in Solar Tribune’s interview with Esdec’s CEO of U.S. operations, Bart Leusink).

Photo source: Esdec

Lastly, solar installers who manage to integrate a handful of standard solar designs for common roof types will find design time and costs drop. Rather than create a fully custom solar installation design for each project, best practice says to identify when designs can be reused or adapted and have the solar design completed more quickly for the customer. They’ll get their solar panels installed sooner, need to pay less for design labor, and everyone involved will be better off for it.

Innovative Market Disruptions to Customer Acquisition

From the perspective of solar installers, becoming creative with their part of the process can be critical. Finding innovative ways to increase their market reach and decrease their customer acquisition costs can bring down the overhead costs for solar installers. Many organizations have harnessed new software solutions to these issues, such as centralized marketplaces to address inefficiencies in supply chain processes. Other solar installers have notably taken to embracing online platforms and e-commerce to more effectively and affordably reach customers. These digital solutions increase the total efficiency of finding customers and installing solar, which can in the end bring the soft costs (and overall costs) down for the consumer.

Embracing the Second Life of Components

The solar industry is, in the grand scheme, rather young, and so the conversations and actions related to end-of-life equipment is starting to really heat up for the first time. While much of the focus on used solar equipment has focused on how to dispose of and/or recycle solar equipment in an environmentally responsible manner, some growing buzz has come from finding ways to effectively reuse old equipment. Whether that equipment comes from old installations a specific installer replaces or from “developing a marketplace for what happens with the second life of components,” effectively embracing used, recycled, or refurbished parts can drop down supply chain costs– not to mention the sustainability benefits of reusing products and avoiding their disposal needs.

Photo source: Saur Energy

Campaign to Reduce Local Solar Permitting Costs and Other Bureaucratic Processes

The process to get new solar projects permitted can be notoriously cumbersome, especially because every jurisdiction (both local and state governments) can have a different process that installers and customers must follow. This variance requires significant additional resources for companies conducting solar system installations, both in terms of time and money. Additionally, these lengthy permitting processes often result in customers purchasing their solar system but needing to wait long times before getting them installed, frustratingly pushing out the time period before the savings from the solar system will pay back the upfront costs.

These types of soft costs are difficult to address on a case-by-case basis for individual customers, but a number of programs and campaigns have been organized by the solar power industry to try and solve the problem. The Department of Energy (DOE) implemented the SunShot Prize competition to “motivate local governments, communities, solar companies, and electric utilities to collaborate towards improving the ‘going solar’ experience.” Similarly, the DOE-funded SolSmart program recognizes “communities that have taken key steps to address local barriers to solar energy and otherwise foster the growth of mature and local solar markets.” By highlighting the local jurisdictions who minimize permitting costs and barriers, the SolSmart program holds up examples and road maps for other localities who want to embrace rooftop solar in their communities.

The continued focus of the solar PV industry will likely remain on technological breakthroughs in efficiency and price. While those aspects are certainly critical to solar power’s continued upward trajectory, recognizing that the hardware of rooftop solar doesn’t even account for 40% of the cost to customers should serve as an eye-opener about the vast additional opportunities afforded by attacking solar costs.

About the author: Matt Chester is an energy analyst in Washington DC, studied engineering and science & technology policy at the University of Virginia, and operates the Chester Energy and Policy blog and website to share news, insights, and advice in the fields of energy policy, energy technology, and more. For more quick hits in addition to posts on this blog, follow him on Twitter @ChesterEnergy.